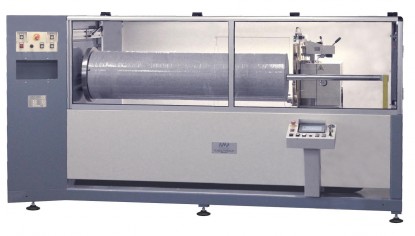

T1000EX

Numerically controlled roll slitter for heavy rolls up to 100kg (220 lbs.) , diam. 40cm (16") and length 200cm (79"). Maximum displacement of the blade carriage from the chuck 200 cm with possibility to load rolls with maximum length 235cm. Available on request for rolls diam 50 cm ( 20" )on requests).

Download data sheetFeatures

- This machine has been designed with the utmost attention to safety features to obtain, for the first time in the market, from IMQ (www.imq.it Italian Institute for Quality Trademarks) the Certification of Examination “CE” for standards 2006/42/EC (Ref. IMQ/300).

- Numerically controlled positioning of the blade carriage with brushless motor and automatic cut with the possibility of programming up to 6 cutting measures for each automatic cycle.

- Numerically controlled positioning of the blade carriage and automatic cut with possibility to program up to 6 cutting measures for each automatic cycle.

- Adjustable blade and roll rotation speed with brushless motors and possibility to choose the roll rotation direction.

- Numerical control for the cutting movement of the blade to the roll to get a slow initial penetration speed in the material, the cut at the preset speed and a slow down near to the cardboard core

- Self centering pneumatic double lock chuck on the cardboard and on the external diameter with possibility to adjust the locking pressure.

- Up to 50 different cutting cycles. All the cutting parameters can be stored into the machine memory and retrieved

- Machine totally closed and highly safe for the operator. Machine totally closed with automatic opening door and safety system that prevents the fall in case of power off or no compressed air in the circuit.

- PLC controlled machine and equipped with a complete diagnostic software to inform the operator of any possible alarm and to display instructions to restart the unit on a touch screen graphic panel.

Browse products by type

Browse products by use