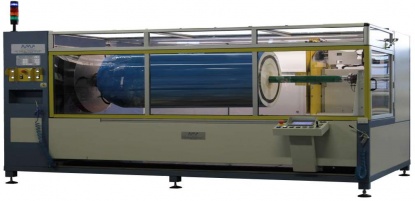

T/1800F

Numerically controlled roll slitter for very big rolls up to diam. 75cm (30"), lenght 200cm (79") and weight 100kg. Max blade displacement from the chuck 175cm (79"). Removable roll shaft.

Download data sheetFeatures

- Numerically controlled positioning of the blade carriage with brushless motor and automatic cut with possibility to program up to 6 cutting measures for each automatic cycle.

- All drives of the machines are brushless. Roll motor, blade motor, blade positioning motors are controlled by a closed loop.

- Adjustable blade and roll rotation speed with brushless motors and possibility to choose the roll rotation direction.

- Blade penetration speed in the roll adjustable on continuous rate with wormscrew movement and brushless motor and possibility to program a slower cardboard cutting speed . Photocell to detect the diameter of the roll.

- Laser pointer to indicate the actual position of the blade on the roll.

- Laser system to measure the blade diameter with automatic adjustment of stop position near the roll shaft and indication of the circularity error. No knob to adjust the forward travel end of the blade carriage.

- Automatic roll diameter adjustment with a measuring photocell to stop the reverse stroke of the blade carriage once the blade is completely out of the roll. The stop position outside the roll can be varied with the machine joystick

- Automatic positioning of the blade at the edge of the roll and automatic return of the blade to the initial position of the automatic cycle

- Self centering pneumatic double lock chuck on the cardboard and on the external diameter with possibility to adjust the locking pressure and adjustable mechanical stop to avoid an excessive pressure of the pliers on the roll in case of soft materials

- Expanding rotary shaft removable from the front of the unit with easy-to-replace plastic grippers along the whole shaft extension.

- Shaft diameter 3" (75 mm) with the possibility of using interchangeable 4" and 5 "shafts.

- Automatic sharpening of the circular knife (both sides) with adjustable sharpening time after a programmable number of cuts using BORAZON grindstones. Blade speed will be set automatically to the optimal sharpening speed during the operation. The auxiliary sharpener is programmable separately from the main sharpener

- Automatic blade cooling system with nebulized water and collection tank in stainless steel. The liquids can be discharged outside of the machine with a tube.

- Automatic blade lubrication and cooling system with adjustable frequency (single or multiple) and lube on/off times with possibility to use pure silicon oil or water mixed with silicone glycol

- Door on the rear side of the machine for easy access to the blade carriage with sensor to stop immediately the machine when it has been opened

- Machine totally closed and highly safe for the operator.

- Automatic opening of the machine door with pneumatic cylinder and safety system to avoid the sudden drop in case of sudden power off or sudden interruption of the compressed air supply

- LED lights for a clear illumination of the machine and signal tower to indicate the actual machine status

- Up to 50 different cutting cycles. All the cutting parameters can be stored and retrieved into the machine memory from each program

- PLC controlled machine equipped with a complete diagnostic software to inform the operator of any possible alarm and includes instructions to restart the unit on a touch screen graphic panel

Browse products by type

Browse products by use